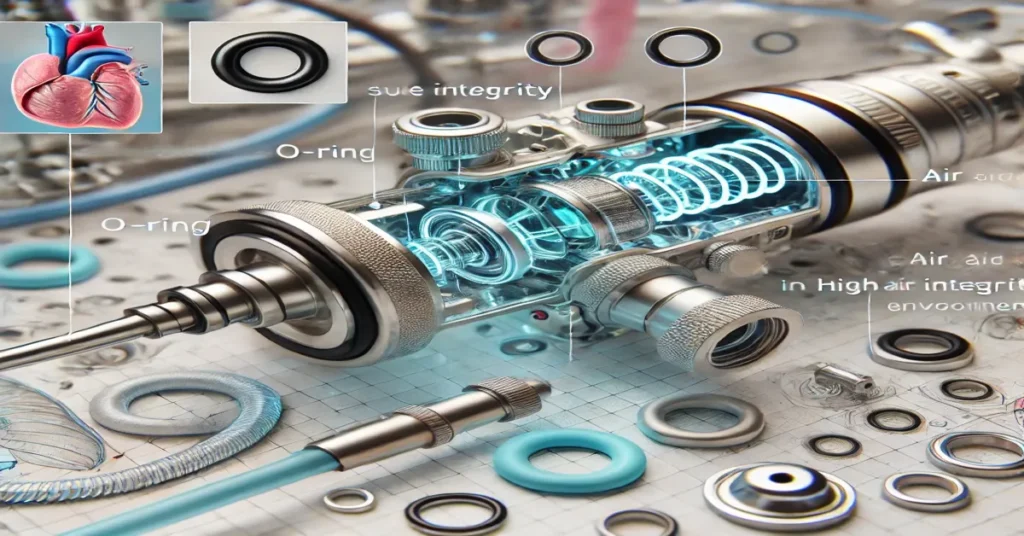

Endoscopy is a vital medical procedure used to visualize the interior of a patient’s body, helping doctors diagnose various conditions. One of the often-overlooked yet essential components in medical devices like endoscopes is the O-ring. This small yet powerful piece ensures the proper functioning of the equipment, particularly in high-pressure environments. In this article, we will explore how O-rings are crucial for both endoscopy and other high-pressure equipment, their role in maintaining safety, and why choosing the right material is key for optimal performance.

Understanding Endoscopy and the Role of O-Rings

Endoscopy is a procedure that involves inserting a thin tube, called an endoscope, into the body to examine internal organs. Endoscopes are complex devices equipped with various channels, and many of their components rely on O-rings to prevent fluid or air leaks during procedures. These rings ensure the endoscope maintains its pressure integrity, which is crucial for delivering precise imaging during the examination. Without these small seals, the device could malfunction, leading to compromised diagnostics and patient care.

An O-ring is a circular rubber seal that fits into grooves to prevent the escape of gases or liquids, especially in high-pressure systems like those found in medical equipment, automotive engines, or industrial machinery. In endoscopy, O-rings are especially important in areas like the air and water channels of the scope, where maintaining tight seals is essential for proper operation.

How O-Rings Support High-Pressure Environments in Medical Devices

In high-pressure equipment such as endoscopes, maintaining a leak-proof environment is paramount. The air and water channels in an endoscope, for instance, rely on O-rings to keep them sealed off, ensuring smooth passage for fluids without leakage. This sealing capability is particularly important during procedures where controlled pressure is necessary to expand areas for clearer viewing or for introducing medication through the scope.

O-rings not only prevent leaks but also help protect the delicate internal components of the endoscope from contamination by bodily fluids. This dual function of sealing and protection makes O-rings invaluable to the performance and longevity of the device.

Material Selection for O-Rings in High-Pressure Equipment

Choosing the right material for O-rings is crucial in high-pressure environments. In the context of endoscopy, O-rings made from materials like silicone, nitrile, and fluorocarbon are most commonly used due to their ability to withstand high pressures and resist chemical degradation from sterilization procedures. Each material has specific properties that make it suitable for different applications:

- Silicone O-rings are ideal for their flexibility and temperature resistance, making them useful in endoscopes that are repeatedly sterilized at high temperatures.

- Nitrile O-rings offer excellent resistance to oil and chemicals, which is beneficial for devices exposed to a range of cleaning agents.

- Fluorocarbon O-rings provide the highest resistance to chemicals and extreme temperatures, making them essential in high-end medical devices.

By selecting the right material, medical professionals can ensure that their equipment performs reliably under high-pressure conditions, extending the lifespan of the device and ensuring patient safety.

The Importance of O-Ring Maintenance in Endoscopy

Maintaining the integrity of O-rings in high-pressure medical equipment, such as endoscopes, is critical for avoiding equipment failure. Regular inspection and replacement of these seals are essential steps in ensuring that medical procedures are conducted without interruptions or complications.

Endoscopes, which are reused multiple times, often undergo intense sterilization processes. High heat and cleaning chemicals can wear down O-rings over time, causing them to lose their elasticity or become brittle. This degradation can lead to leaks, compromising the device’s ability to maintain the necessary pressure.

Therefore, routine checks and timely replacement of O-rings can prevent unexpected failures during medical procedures. This proactive maintenance practice not only guarantees optimal performance but also ensures the safety of both the patient and medical personnel.

O-Rings Beyond Endoscopy: Their Versatile Application in Other Industries

While O-rings are critical in medical devices like endoscopes, their use extends far beyond the medical field. In industrial machinery, automotive engines, and aerospace equipment, O-rings perform similar functions by preventing the leakage of fluids and maintaining pressure integrity. Whether in oil pipelines, hydraulic systems, or gas cylinders, O-rings play a vital role in ensuring that high-pressure equipment operates smoothly and safely.

In the automotive industry, for instance, O-rings are commonly used in engines to seal oil passages and coolant systems. This ensures that critical fluids do not escape, which could otherwise lead to overheating or mechanical failure. Similarly, in industrial machinery, O-rings help maintain the integrity of hydraulic systems that power heavy-duty equipment.

Given their widespread application, it’s easy to see how O-rings are crucial for the safety and efficiency of various high-pressure systems.

FAQs

1. What is the main function of O-rings in endoscopes?

O-rings in endoscopes serve to prevent fluid or air leaks in high-pressure areas, ensuring the device operates efficiently and maintains clear imaging during procedures.

2. How often should O-rings be replaced in medical devices?

O-rings should be inspected regularly and replaced when signs of wear, such as cracking or loss of elasticity, appear. Frequent sterilization can accelerate the need for replacement.

3. Can O-rings withstand the sterilization process used for endoscopes?

Yes, but the material of the O-ring must be chosen carefully. Silicone, nitrile, and fluorocarbon O-rings can withstand high temperatures and chemical exposure during sterilization.

4. Are O-rings used in other high-pressure systems outside of the medical field?

Yes, O-rings are widely used in automotive engines, industrial machinery, and aerospace equipment to prevent fluid or gas leakage in high-pressure systems.

5. What factors should be considered when choosing an O-ring for a high-pressure application?

Factors such as material compatibility, temperature resistance, chemical exposure, and pressure levels must be considered to ensure the O-ring performs optimally under high-pressure conditions.

Conclusion

O-rings may be small, but their role in ensuring the smooth operation of high-pressure equipment like endoscopes cannot be overstated. In medical devices, especially endoscopes, these seals prevent leakage and contamination, while maintaining the equipment’s pressure integrity. Selecting the appropriate material and conducting regular maintenance are vital steps in preserving the lifespan and functionality of both medical and industrial equipment. The versatility of O-rings makes them indispensable across a wide range of high-pressure applications, from healthcare to heavy machinery. By understanding their significance, professionals can ensure better performance, improved safety, and enhanced durability of their high-pressure systems.